Jobsite safety should be an important part of your crew’s workday, every day. Though it’s sometimes easy to lose focus of the safety protocols while on a job, especially if you are not on-site managing a project, instilling a culture of safety can keep your team members healthier, while at the same time increasing efficiencies.

Belgard® has six easy ways to create a safer environment and reduce injuries.

Use Vacuum Lifters

Hardscaping materials are heavy. Carrying them by hand can strain your team’s muscles, tendons, and bones. Incorporating vacuum lifters that utilize suction systems to place hardscapes can make this process easier and reduce your overall workload. Whether it’s grabbing large pavers or lifting retaining wall blocks, this equipment reduces injuries and long-term strain on the body, while also decreasing your labor costs and speeding up the entire process. Your crew will love you for it!

Respiratory Protection is an OSHA Standard

Keep your team safe by providing masks. They are a small investment yet play a key role in protecting workers from exposure to dust. OSHA (Occupational Safety and Health Administration) strongly suggests that you use respiratory protection as stated in the new OSHA 29 CFR 1926.1153. If an employer requires an employee to wear a mask, they must follow all tenants of the OSHA respiratory protection standard, which include:

- dust and respirable silica monitoring and abatement

- medical assessments of all workers required to wear N-95 masks

- fit testing of the N-95 which includes adopting a facial hair policy that requires employees to be clean shaven or the company has to go to a positive pressure system for dust control

Available in different styles, these special masks are specifically made to ensure the safety of your crew as they work at hardscape jobsites where dust and air particles are commonplace. These masks provide layers of protection and greater filtration than normal disposable masks. Add masks to your PPE (personal protective equipment) regimen, and your employees will enjoy maximum protection, comfort, and breathability along with a greater peace of mind as they go about their workday.

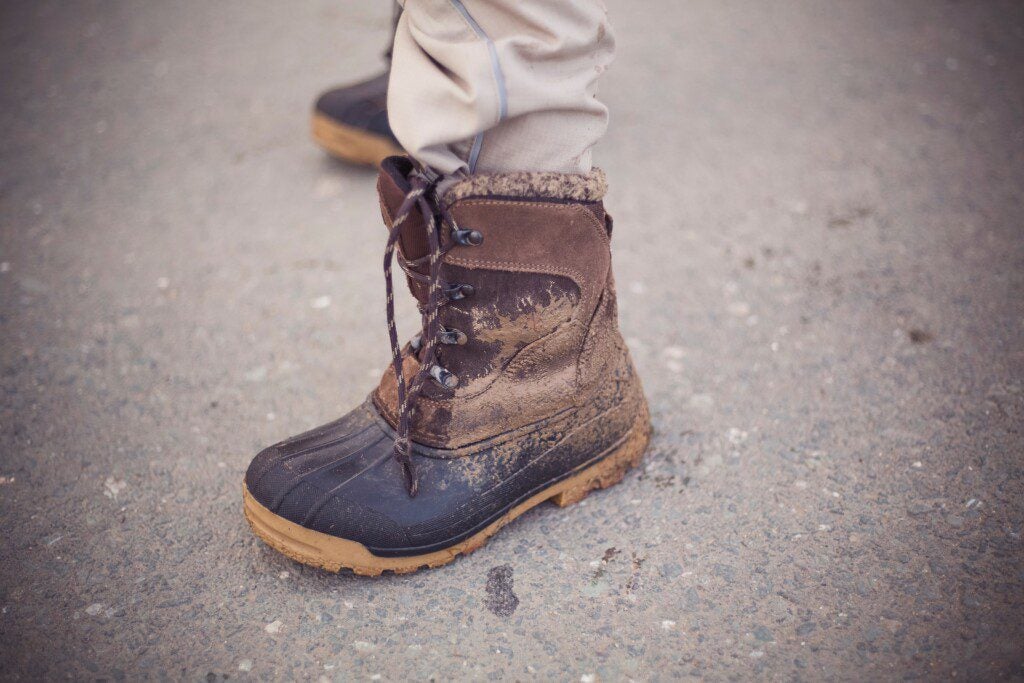

Boot Up for Toe Protection

When handling hardscapes, gloves are a necessity on the jobsite. However, protective footwear, such as steel-toed boots, may be harder to enforce for your crew. Steel toes offer serious impact protection for dangerous work environments. There are also other materials, but steel toes are more resistant to cracking, and more often have a larger toe box, which can provide more toe room.

Composite toe boots are lighter and because they are not a thermal conductor, the wearer is less likely to feel the heat or cold, making them ideal for work in extreme weather conditions. Like steel toes, alloy toes provide good impact protection but with a lighter weight, making them more comfortable during long shifts. The lightweight material also provides even more toe room than steel caps. However, since they’re also made from metal, alloy toes are not as comfortable in extreme temperatures. An even better foot safety solution would be to require metatarsal guards. Modern technology with this type of guarding now offers a Kevlar type tongue that gets hard upon impact but remains flexible during normal wear.

You know the type of work and conditions on your jobsite, so recommend the protective footwear that’s best for your crew to work safely.

Safeguarding the Eyes is a Must

Debris from cutting and sawing pavers or blocks can become a hazard. Material can potentially fly into the eye of the person performing the work or even someone simply walking by. Safety glasses are a must on jobsites, but when cutting/sawing pavers, goggles and a face shield should be required. Safety glasses are considered “entry level” eye protection. In dusty situations, you need a seal around the eyes to prevent debris from getting into the eyes. Further, for cutting where you know chips are flying, you need to wear a face shield to protect the face (mouth, nose, teeth, etc…) from being damaged when chips fly.

Staying Hydrated is Key

Encourage your team to drink lots of fluids and stay hydrated, even if your business is not in a warm climate. Dehydration can lead to fatigue, dizziness, and lack of concentration, all of which can contribute to lowered production from a crew member — or worse, an accident. If your business is located in an area with high temperatures, dehydration can occur quickly. It is extremely important to have plenty of water on site and advise your crew to take numerous water breaks during the workday.

Be Vocal About Safety

Safety on the jobsite should be ingrained in your crew. However, creating a culture of safety means communicating what to do and not to do every day.

Andy Welch, General Manager of Oriole Landscaping in Virginia consistently stresses safety to his group of 25 employees. “We do a weekly safety meeting to keep it top of mind,” he says. “During the meeting, we cover a range of topics, especially those that show how equipment works and the limits of a machine. Most accidents happen when a machine is used for something it isn’t meant to do.”

Welch stresses that communication between employees is the easiest form of safety. He encourages his crew to speak up if there are safety issues and look out for each other. Another step he takes to reduce the risk of potential injuries is to keep a tidy jobsite. “A messy worksite with uneven dirt, cut rock on the ground, or straps laying around can lead to accidents,” he adds. “Making small corrections as you go along keeps it safer.”

“For example, when guys are digging out for a patio, there’s going to be a disturbed area, so we make sure to rake it over and perform some minor grading to keep it level. We also use mats to prevent machines from making ruts. In most cases, our hardscape crew members are carrying things or using a wheelbarrow. So, they are moving without seeing what’s underfoot. Keeping areas tidy prevents them from stepping on something or rolling an ankle on an unlevel surface.”

Safety is an important part of work, especially in the hardscape business. We hope you can incorporate these easy tips to create a safer jobsite and increase efficiencies. Good luck and stay safe!

For more resources, check out our resource page.